Crucial Tips for Successful Welding Inspection Madison Providers

Crucial Tips for Successful Welding Inspection Madison Providers

Blog Article

Understanding the Fundamentals of Welding Examination to Ensure Quality and Safety

In the world of modern-day design, welding inspection stands as a foundation for guaranteeing both the quality and security of structural productions. What are the subtleties of these evaluation approaches that make them essential for keeping architectural stability?

Significance of Welding Evaluation

In the realm of industrial fabrication, the relevance of welding inspection can not be overstated. Welding examination plays a critical duty in making certain the integrity, security, and longevity of bonded structures (Welding Inspection Madison).

The process of welding naturally includes complicated variables, consisting of temperature, material buildings, and ecological problems, every one of which can affect the top quality of the weld. A complete inspection determines defects such as cracks, porosity, and insufficient combination, which can compromise the toughness and integrity of the weld. By identifying these problems early, rehabilitative actions can be taken, thus minimizing the risk of failing and associated prices.

Furthermore, welding inspection adds to governing compliance, as several sectors are governed by strict security standards and standards. Failure to stick to these laws can lead to lawful responsibilities and economic charges. Ultimately, welding inspection not only safeguards physical frameworks yet additionally safeguards human lives and supports industry reputations.

Trick Welding Examination Techniques

Although welding evaluation is vital to guaranteeing the top quality and safety and security of bonded structures, it is the specific approaches utilized that establish the performance of the inspection process. Trick welding examination techniques can be extensively categorized into non-destructive testing (NDT) and damaging screening.

Ultrasonic and radiographic testing are extra sophisticated strategies that enable inspectors to evaluate the interior honesty of the weld. Ultrasonic screening utilizes high-frequency acoustic waves to identify interruptions, while radiographic testing employs X-rays or gamma rays to create a picture of the weld's inside. Magnetic fragment testing and fluid penetrant testing are surface examination approaches made use of to situate surface and near-surface flaws. In comparison, damaging testing techniques entail physically cutting the weld or damaging to analyze its mechanical homes. These thorough examination approaches make sure that welds satisfy industry standards and security needs, therefore making sure structural honesty and efficiency.

Role of Qualified Examiners

Qualified inspectors play an essential function in the welding inspection procedure, making sure that all welds follow rigorous market requirements and safety laws. Their experience is essential in identifying problems or abnormalities that might endanger the architectural integrity of a weld. By meticulously checking out each weld, certified examiners assist stop possible failures that could bring about expensive fixings or hazardous accidents.

To become certified, examiners have to go through strenuous training and testing, which familiarizes them with numerous welding methods, materials, and screening methods. This detailed understanding allows them to review weld quality efficiently and make educated judgments about their safety and dependability. Moreover, certified examiners are skilled in interpreting specifications and plans, making certain that the welding job straightens with the job's layout needs.

An integral part of their function is to document their findings thoroughly, supplying an in-depth document of the examination process. This paperwork is important for traceability and accountability, serving as an official document of conformity with market criteria. Certified inspectors likewise play a vital function in facilitating interaction in between job stakeholders, offering recommendations and insights to boost welding methods and results. Their payment is indispensable in maintaining high degrees of quality and safety and security in welding procedures.

Devices Utilized in Welding Examination

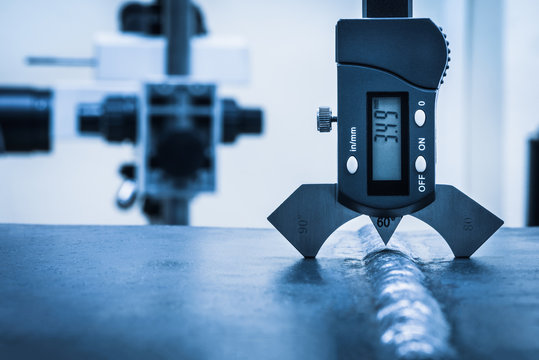

Welding inspectors count on a variety of specialized tools to execute their responsibilities effectively, making certain each weld satisfies the needed criteria. Amongst these tools, aesthetic inspection help like magnifying glasses and mirrors are essential, enabling inspectors to very closely examine welds for surface defects such as splits, porosity, and undercut. Calipers and fillet weld gauges are necessary for gauging weld dimensions to validate conformity with design specifications.

Advanced devices prolong past visual aids, including non-destructive testing (NDT) equipment. Ultrasonic screening tools are crucial in finding subsurface flaws, using audio waves to disclose internal stoppages without compromising the weld's honesty. Radiographic testing utilizes X-rays or gamma rays to record pictures of a weld's inside, highlighting prospective problems.

Magnetic fragment testing is an additional essential tool, especially for detecting surface and near-surface discontinuities in ferromagnetic products. By applying ferrous fragments and magnetic areas, examiners can identify problems that could otherwise be undetectable.

Dye penetrant inspection is frequently used for non-ferrous products, supplying a contrast-enhanced aesthetic check for surface-breaking problems. Welding Inspection Madison. With each other, these devices make it possible for welding assessors to thoroughly analyze weld high quality, making sure safety and integrity in numerous applications across markets

Ensuring Structural Integrity

Welding procedures have to follow well-known standards and codes, such as those specified by the American Welding Society (AWS) or the International this article Organization for Standardization (ISO) These guidelines make sure that the welds can hold up against operational stress and anxieties and ecological factors. Certified and certified welders play an important role in this process, as their experience ensures that strategies are used properly, reducing flaws such as fractures, porosity, and incomplete blend.

Post-weld examination is an additional necessary part of verifying structural honesty. Non-destructive screening (NDT) approaches, including ultrasonic testing and radiographic screening, are utilized to detect subsurface defects without compromising the bonded framework. These assessments validate that the welds satisfy the called for top quality standards, providing guarantee of their resilience and integrity. Inevitably, guaranteeing architectural stability in welding not just safeguards human lives however likewise secures investments and enhances the long life of engineered frameworks.

Final Thought

The fundamentals of welding inspection are necessary for preserving the quality and safety and security of bonded structures. By executing key inspection methods, such as aesthetic analyses and non-destructive screening, possible flaws that can jeopardize structural stability her response are recognized. Licensed assessors are vital in guaranteeing compliance with market requirements and efficient interaction amongst stakeholders. Using specialized tools further boosts the inspection process, inevitably securing human lives and lengthening the lifespan of welded building and constructions.

Welding assessment plays a critical function in guaranteeing the stability, security, and durability of bonded frameworks.Although welding evaluation is critical to ensuring the quality and security of welded frameworks, it is the particular approaches employed that determine the efficiency of the assessment procedure. Key welding inspection techniques can more be generally categorized right into non-destructive screening (NDT) and harmful screening.Licensed assessors play a pivotal function in the welding assessment process, making certain that all welds conform with stringent market requirements and security regulations.The fundamentals of welding evaluation are crucial for preserving the quality and safety of welded structures.

Report this page